FDM 3D Printing

FDM is the type of 3D printing that you hear about the most outside of industry, odds are if you are just starting to get into 3D printing this is the first step. FDM uses a filament (1) as material, which can be one of most thermoplastics such as ABS, PLA, or nylon. This filament is pulled through a hotend (2) that melts the material and feeds it into the nozzle (3). The nozzle is moved around on a gantry system to build a model (4) but depositing the first layer directly on the build platform (5) and every other layer on the layer before it. This allows for very complex shapes to be built with little added effort from the user, which is why 3D printing is such an appealing technology! However, there are a few guidelines to ensure the shape can print: overhangs and ledges should be avoided, as they create a scenario where material must be placed in a location which nothing below to support it. FDM prints generally have support material to help with these features, which are then removed after the print is complete.

Materials: PLA, ABS, Nylon

Uses: Prototyping, Large Models, Fixtures

Part Complexity: Fine Detail

Cost: $6 + $0.15 per gram

Maximum Part Size: 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches)

Need Even Finer Detail? Try SLA 3D Printing

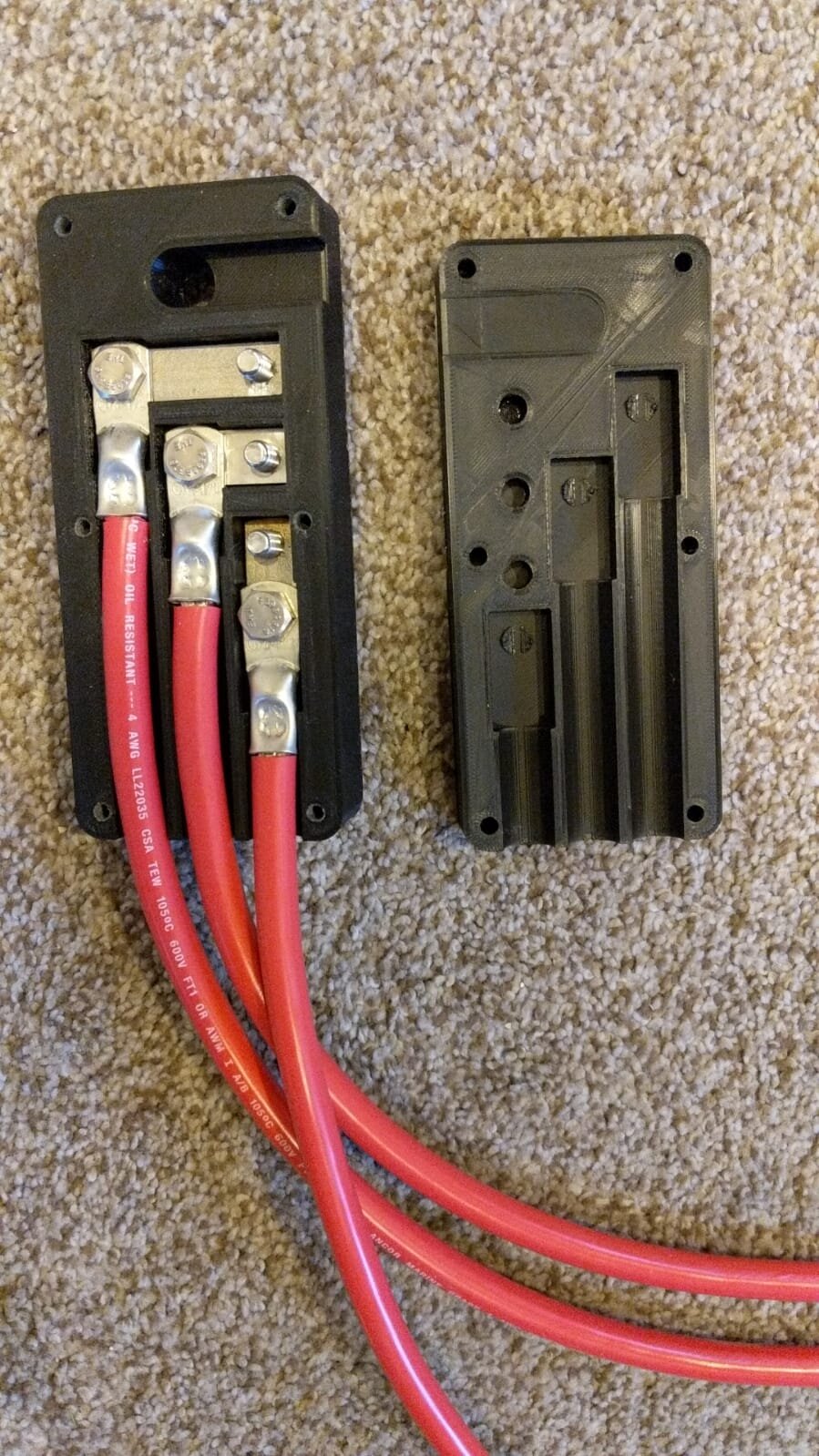

FDM 3D Printing Gallery