SLA 3D Printing

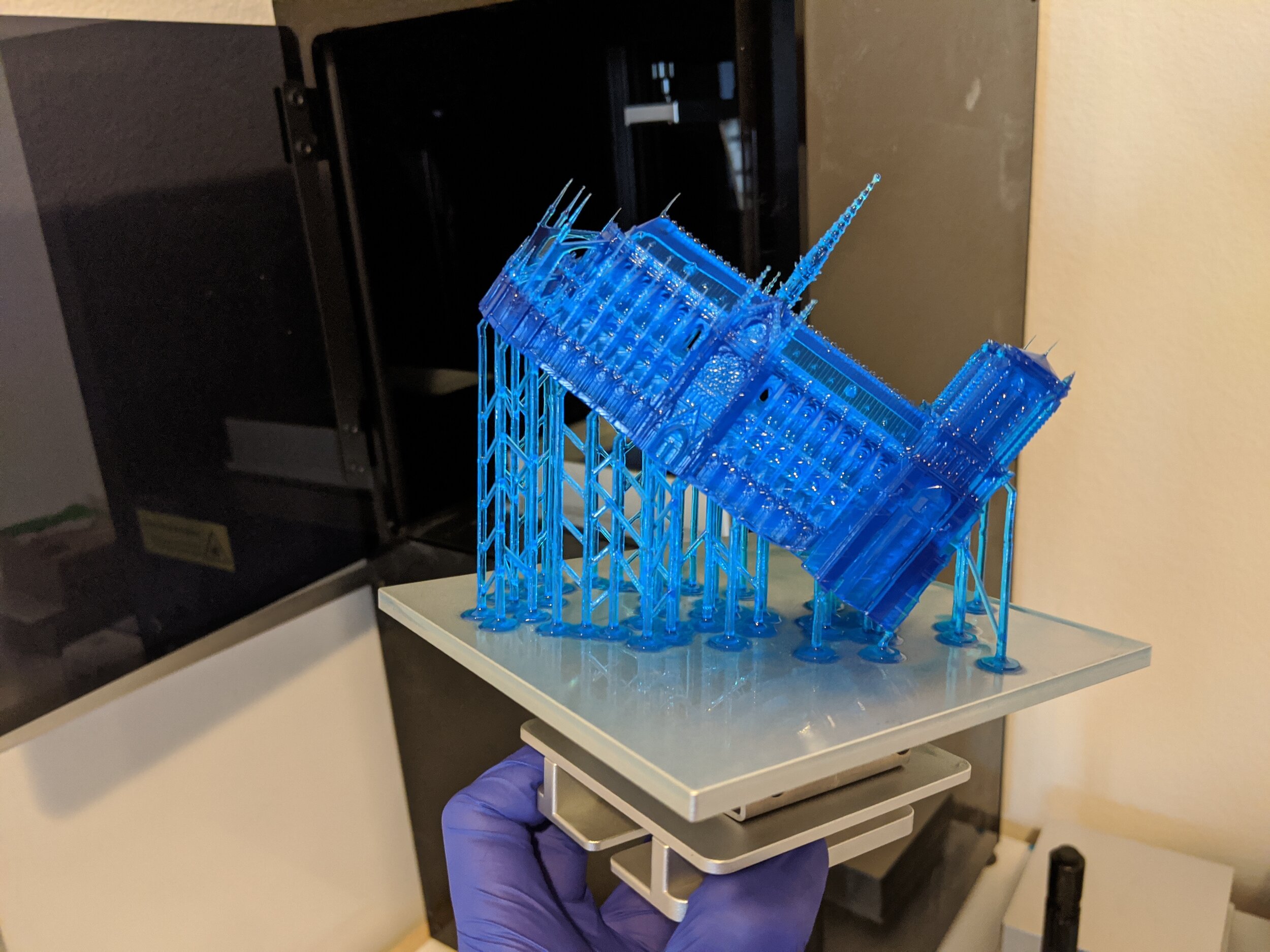

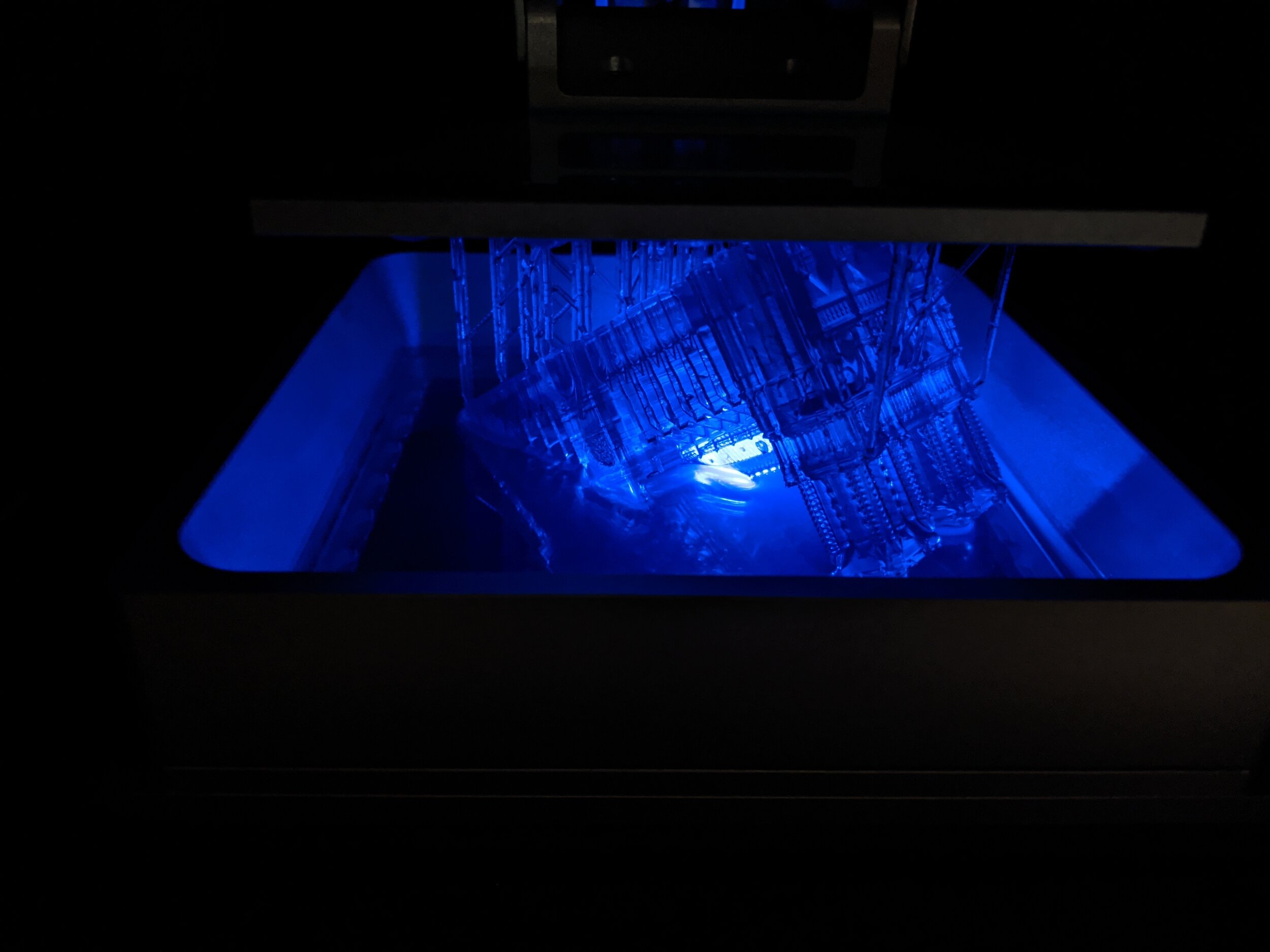

SLA (Stereolithography ) 3D printing is second only to FDM in popularity. It has similar limitations regarding overhangs needing support material, but is produced using a different process. The build platform is suspended above a vat of resin that has a transparent bottom, and each layer is produced by a laser tracing out the cross-section from below, which hardens the resin into a solid plastic. The vat then dips down to ‘pop’ the now solid layer off of the vat bottom and allow fresh resin in, the build platform moves up a tiny bit, and the laser traces out the next layer. SLA prints require more manual cleanup than FDM prints, but the model resolution is much higher.

Materials: UV-cured Resin, Various Compositions

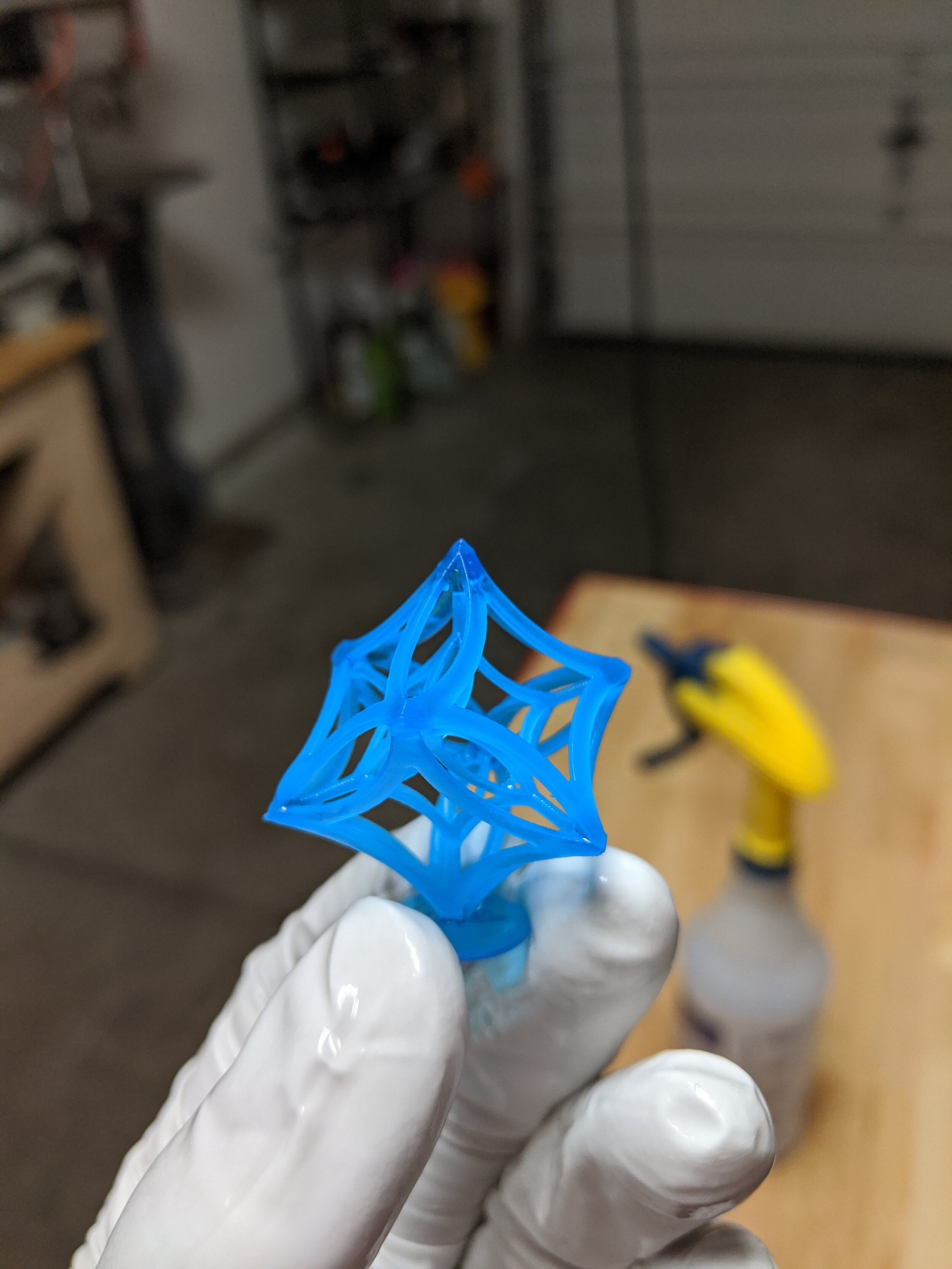

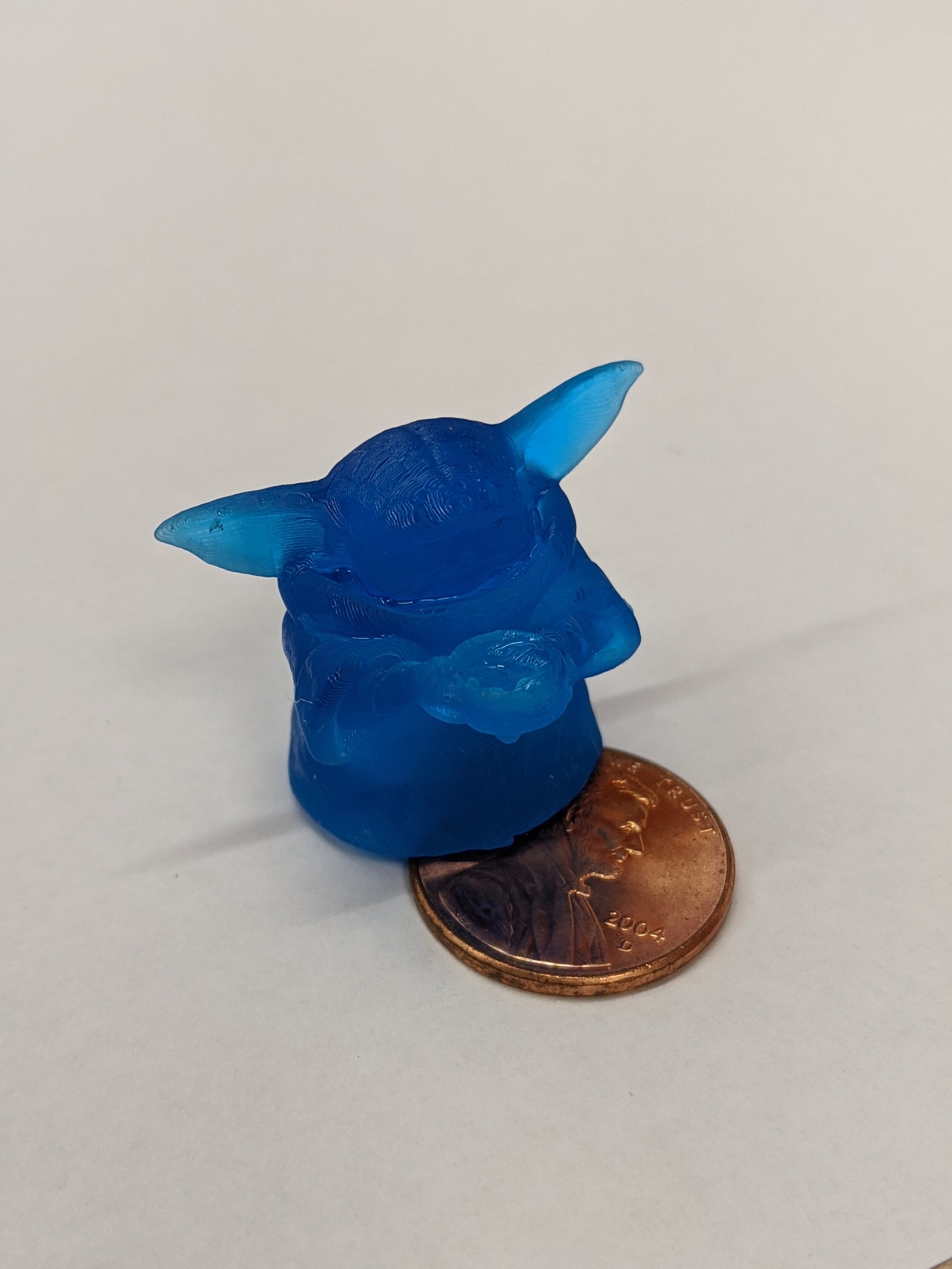

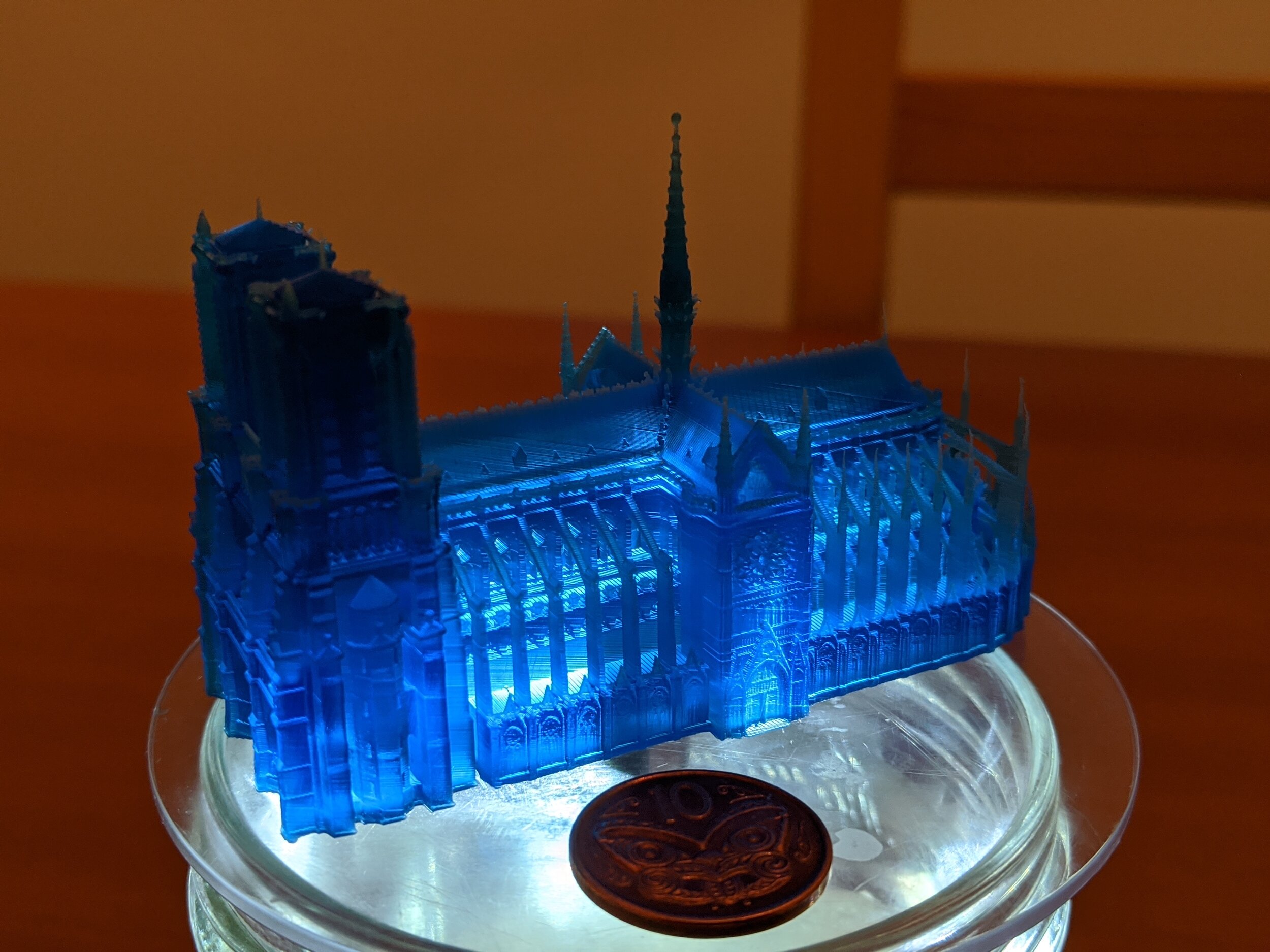

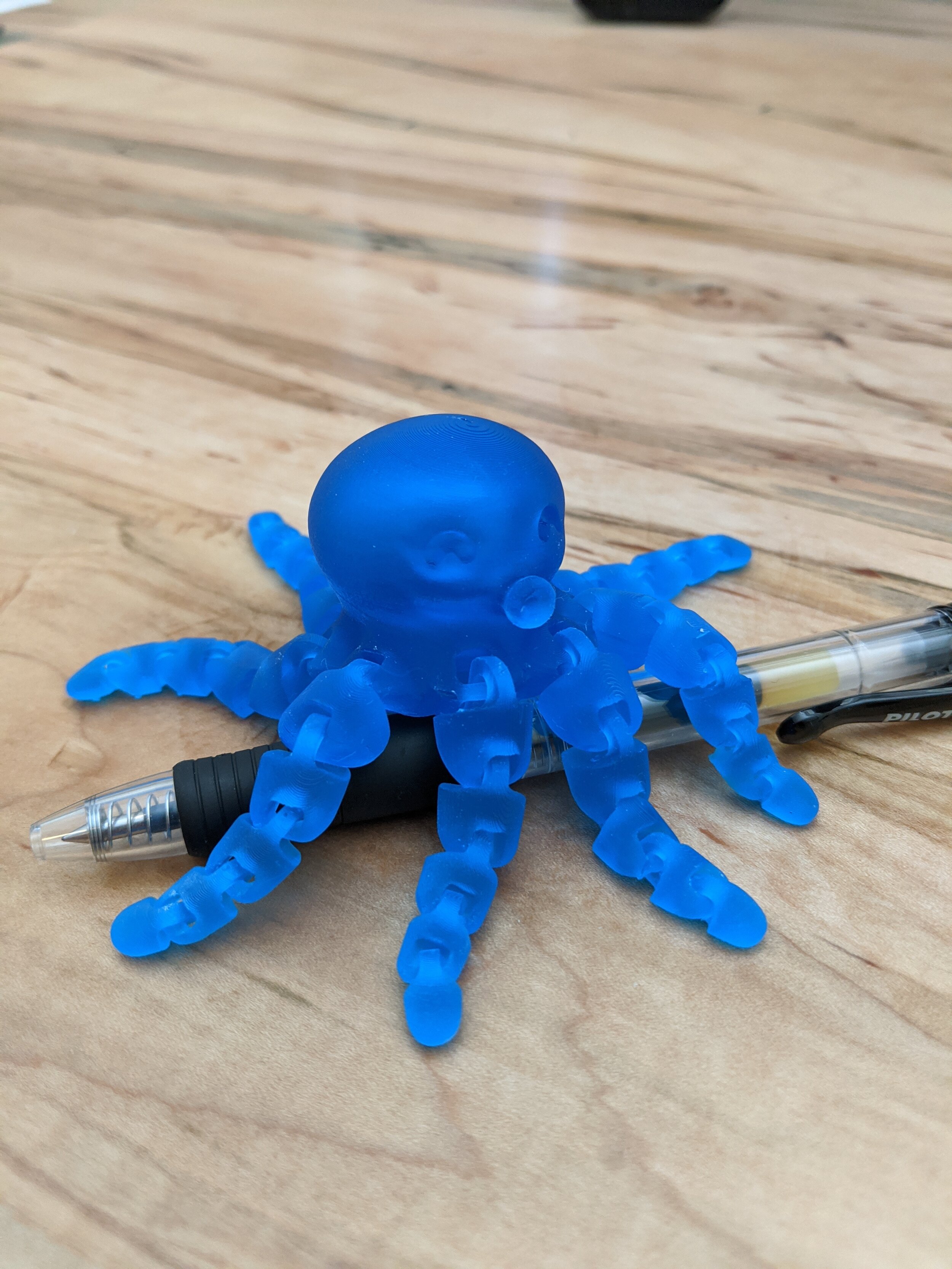

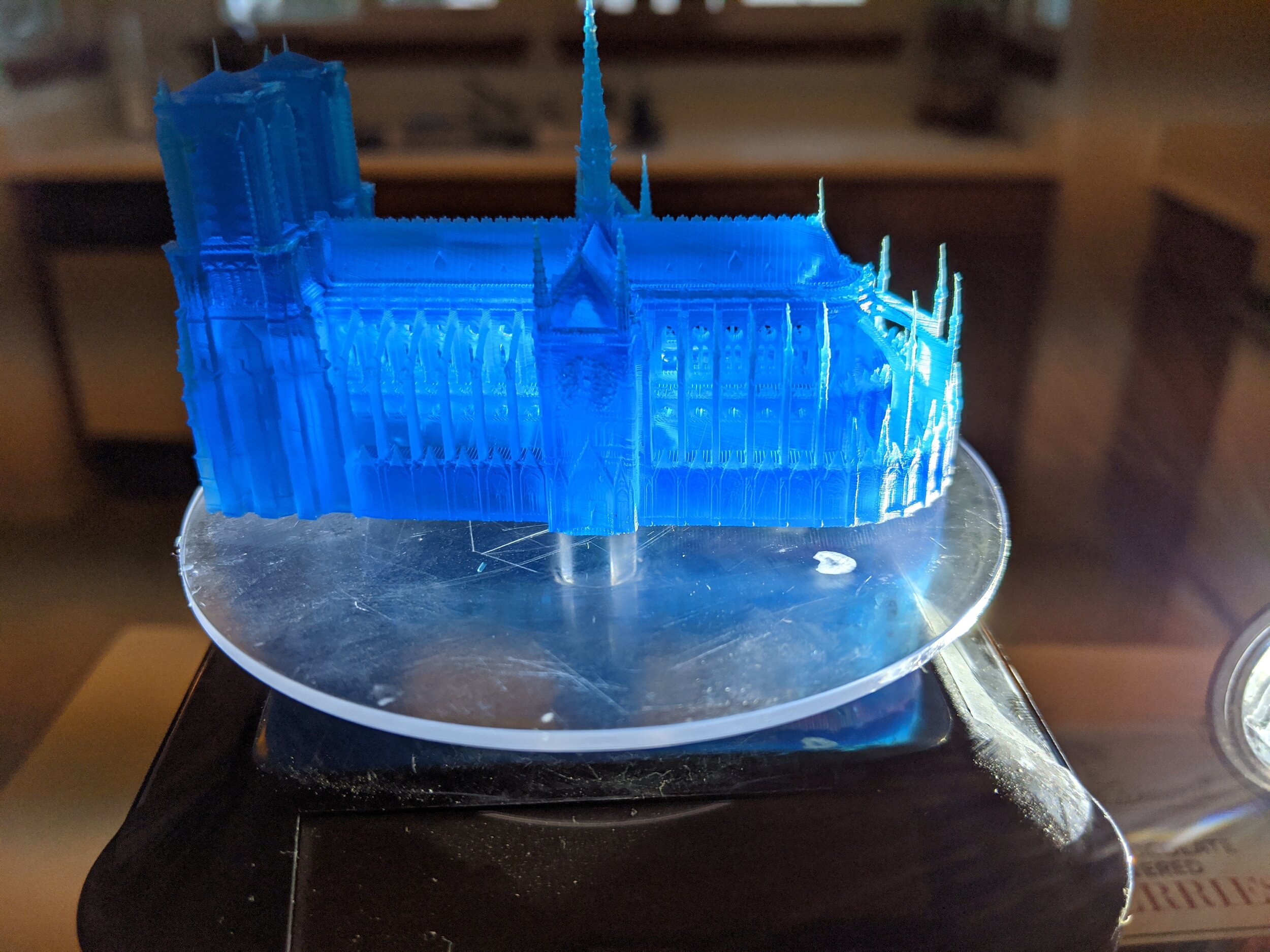

Uses: Model Figures, Lattices , Architectural Models

Part Complexity: Highest Detail

Cost: $8 + $0.17 per gram

Maximum Part Size: 130 x 130 x 180mm (5.1 x 5.1 x 7.0 inches)

Need Larger Parts? Try FDM 3D Printing

SLA 3D Printing Gallery