Milling

Milling is the most versatile machining operation, able to perform all the functions below and more. If you don’t know which ones you need don’t worry! We’ll figure that all out for you. Mills use a spinning cutter in a spindle to cut away material from the part which is held in a vise below. The table and spindle can be moved very accurately to hold tight tolerances on the part, and the cutters can cut a wide range of materials. Additionally, a rotary table can be added to further expand the capabilities of the mill with a rotational axis.

Materials: Metals (Steel, Brass, Stainless, Titanium), Plastics

Uses: Orthogonal shapes mostly, but flexible

Part Complexity: Simple shapes, highest accuracy

Cost: $60 per hour

Maximum Part Size: 11.8 x 5.1 x 10.6 in (300 x 130 x 270 mm)

Is your part more cylindrical than rectangular? Try Milling

Does your part need complex profiles in 2D? Try Waterjet Cutting

Milling Processes

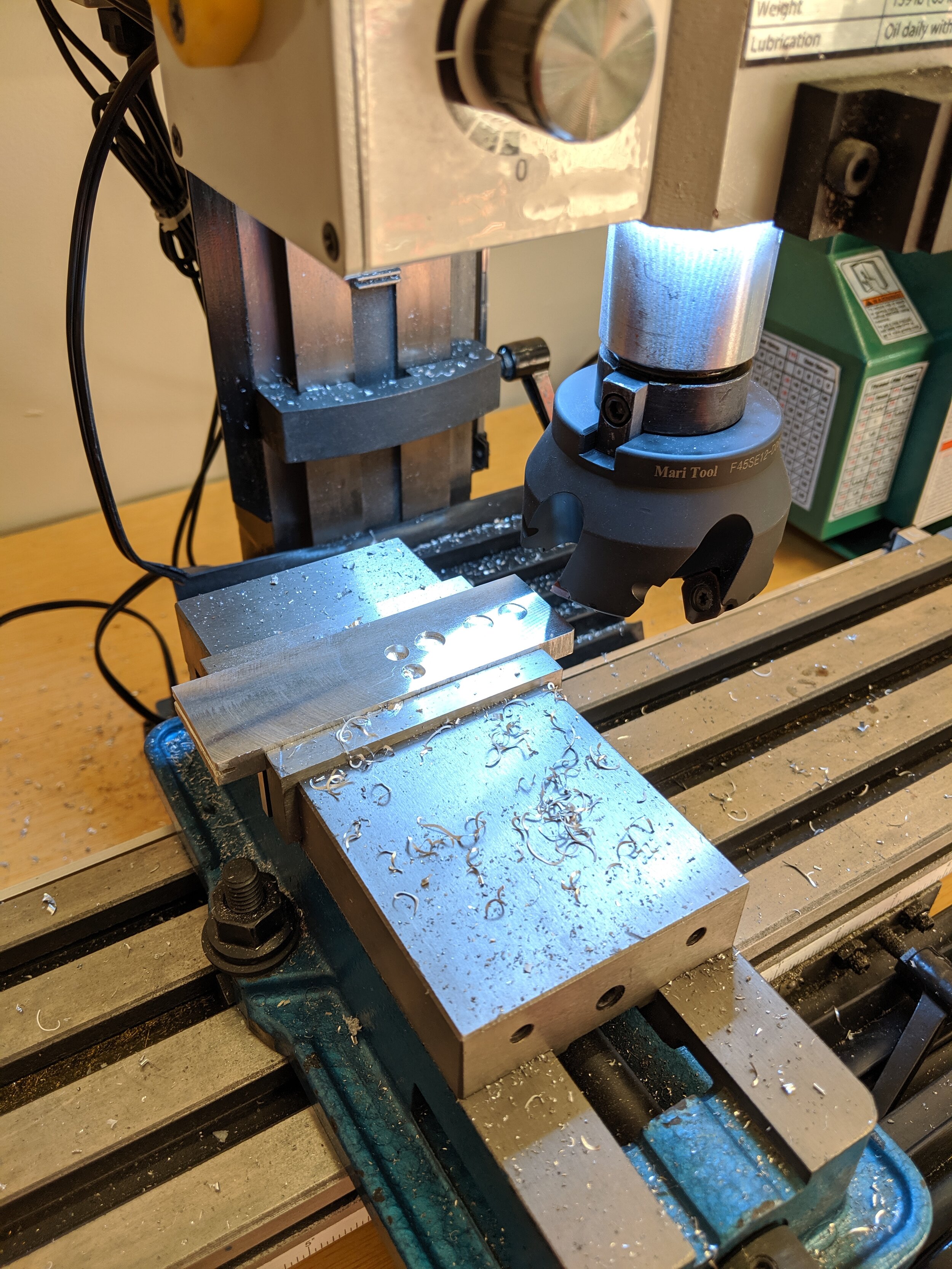

Decking

Decking gives a very flat surface to a part, generally with superior surface finish.

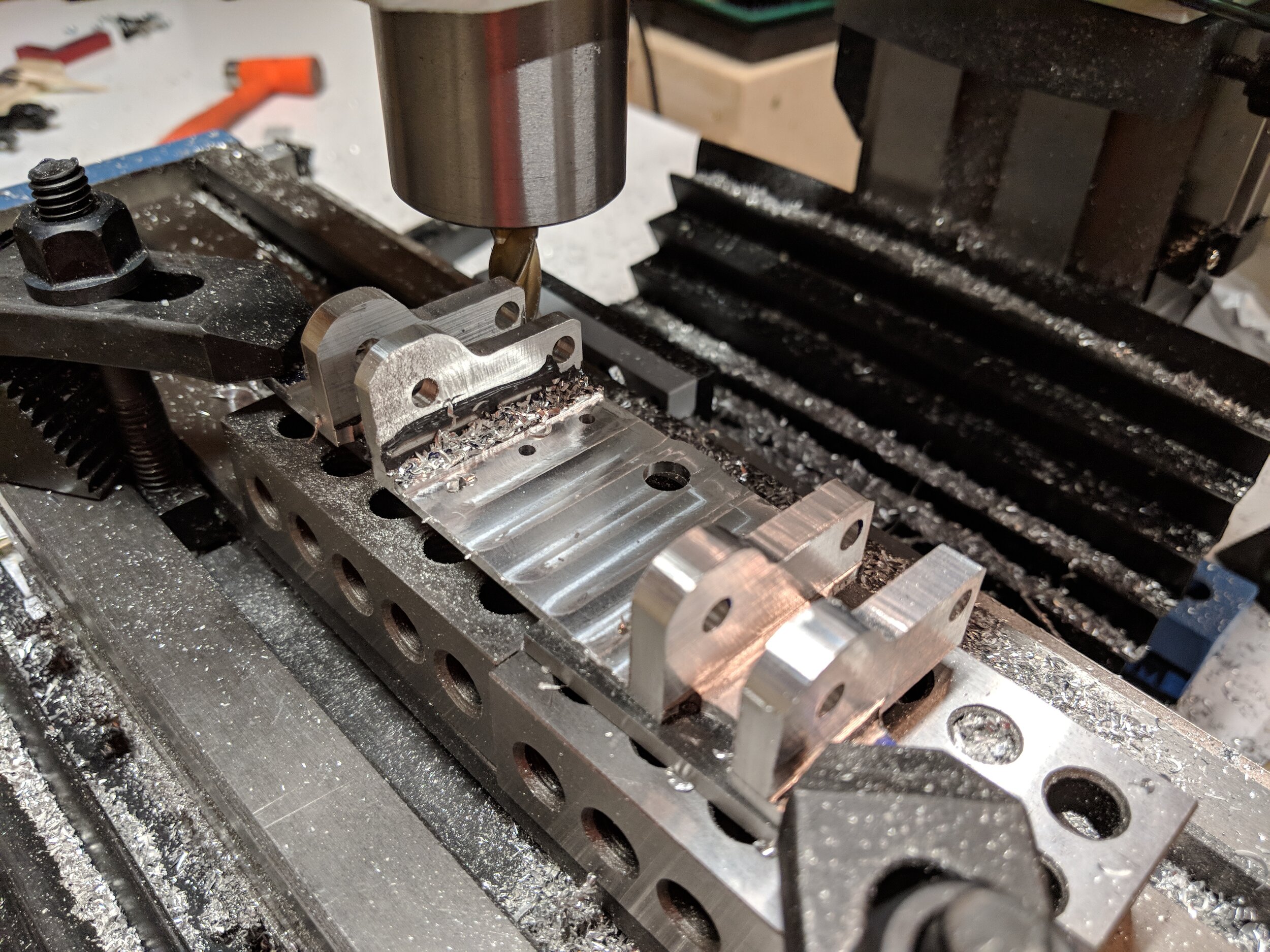

Pocketing

Pocketing rectangular shapes (or combinations of rectangular shapes) is a common and straightforward procedure.

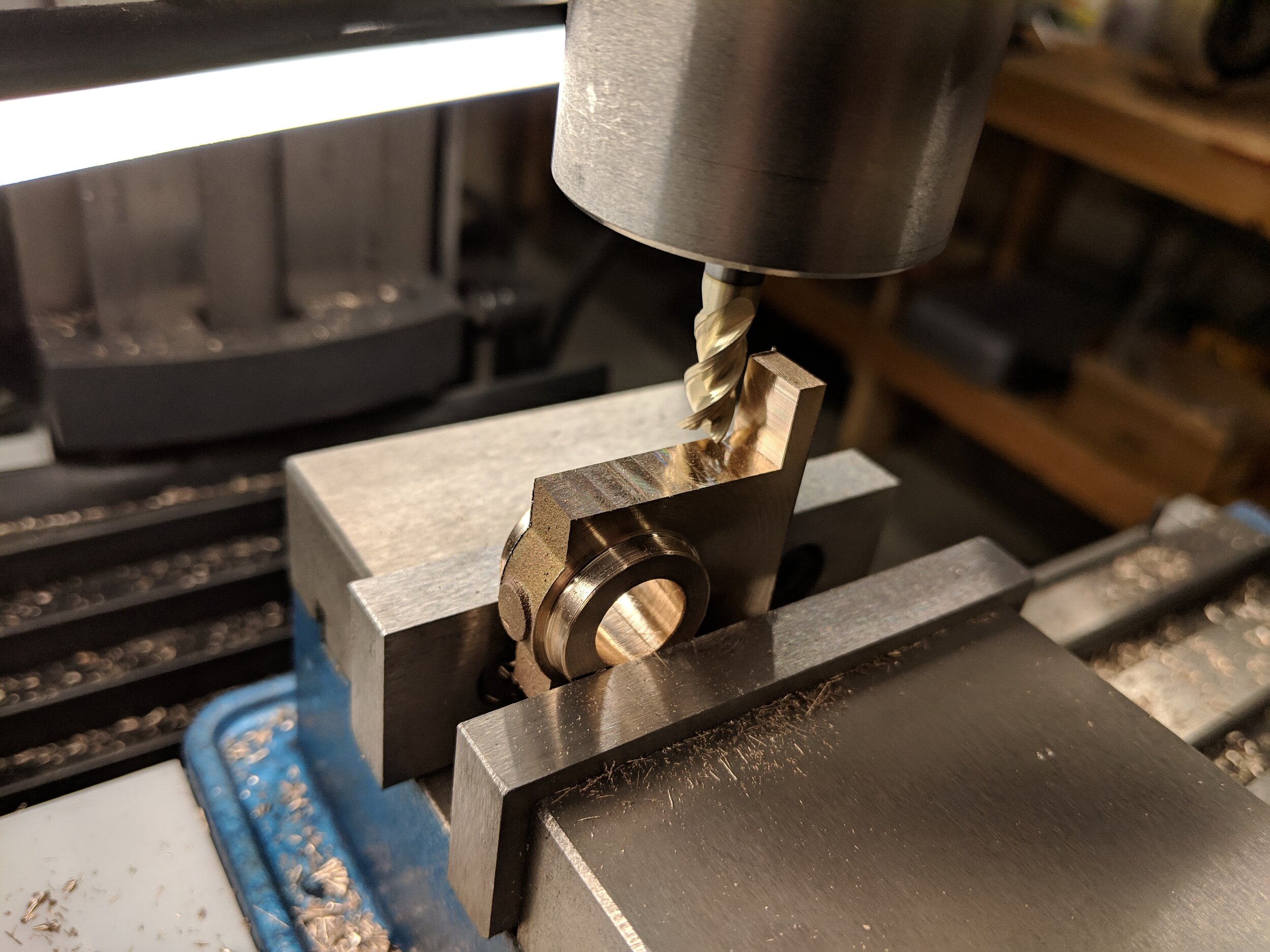

Shouldering/Slotting

Cutting shoulders or slots is quite common and may take any number of orthogonal shapes.

Profiling - Rectangular

Profiling defines the perimeter of the part, and can be easily done for any number of orthogonal edges.

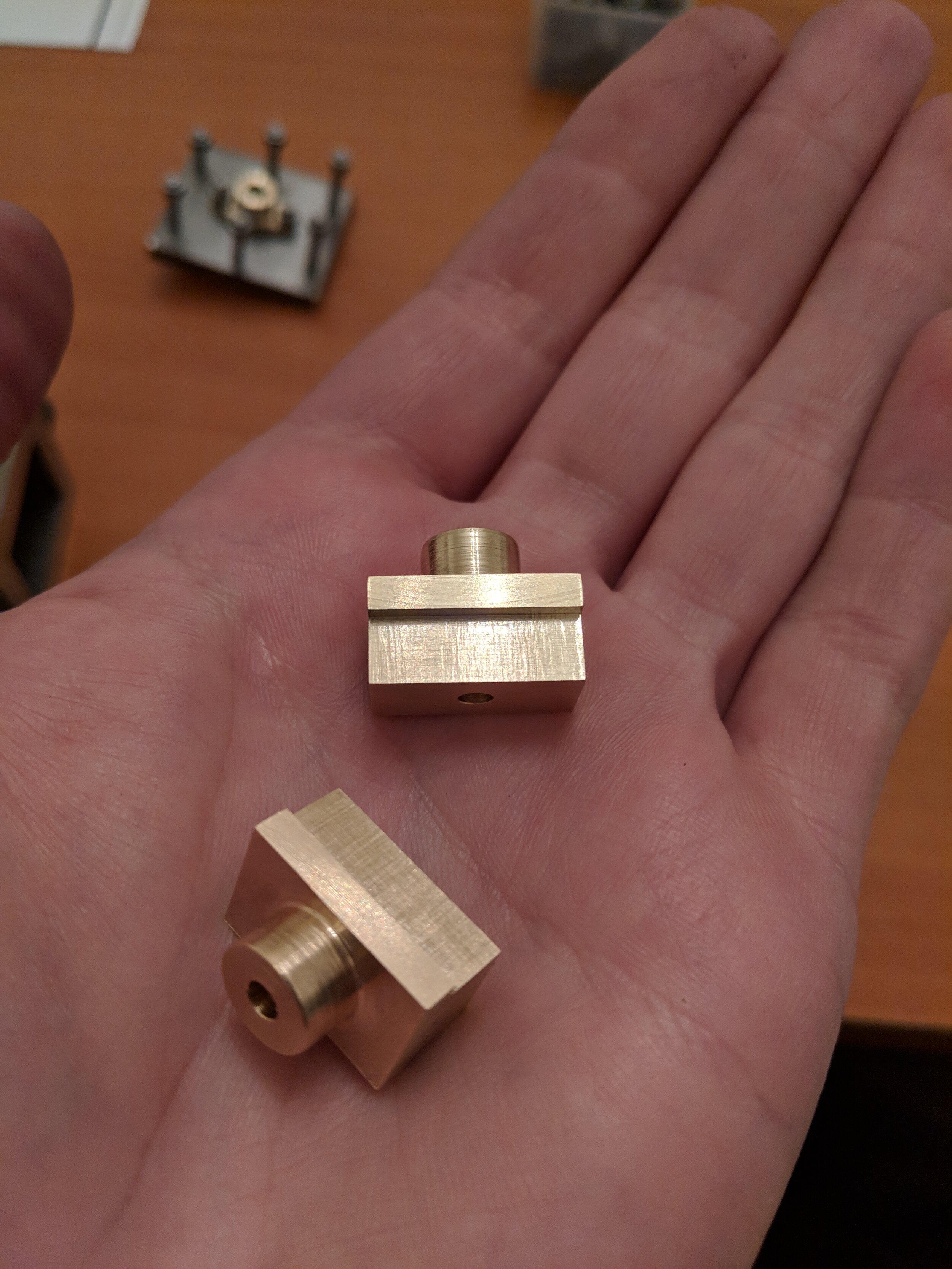

Bolt Hole/Threads Patterns

Holes can be drilled at any X-Y coordinates to produce patterns to match any mating part. Additionally, holes can be blind or through tapped for screw threads.

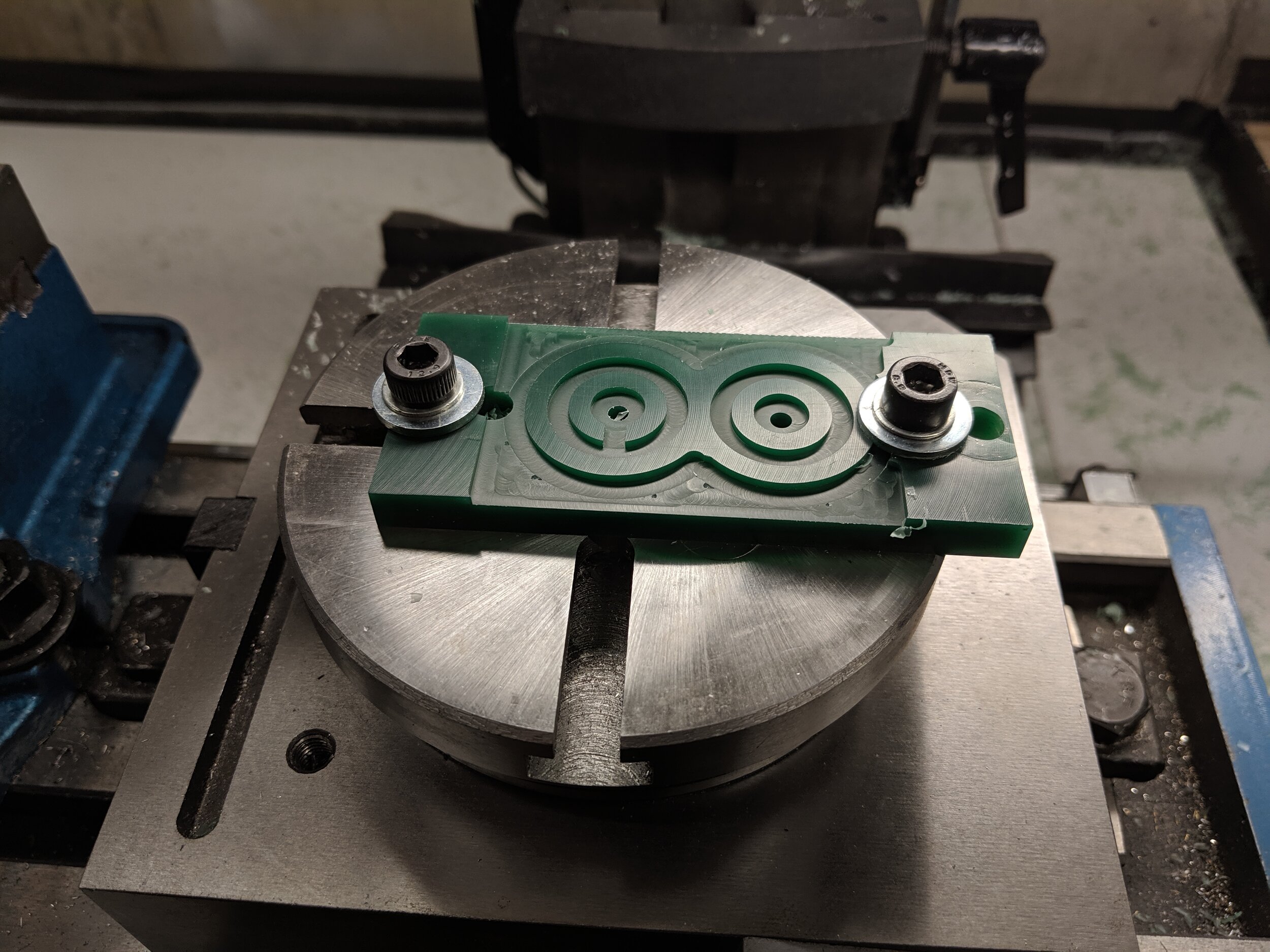

Milling Processes - Rotary Table

Arc Pockets/Shouldering

Cutting perfect circles and arcs for pockets, shoulders, and profiling is now possible.

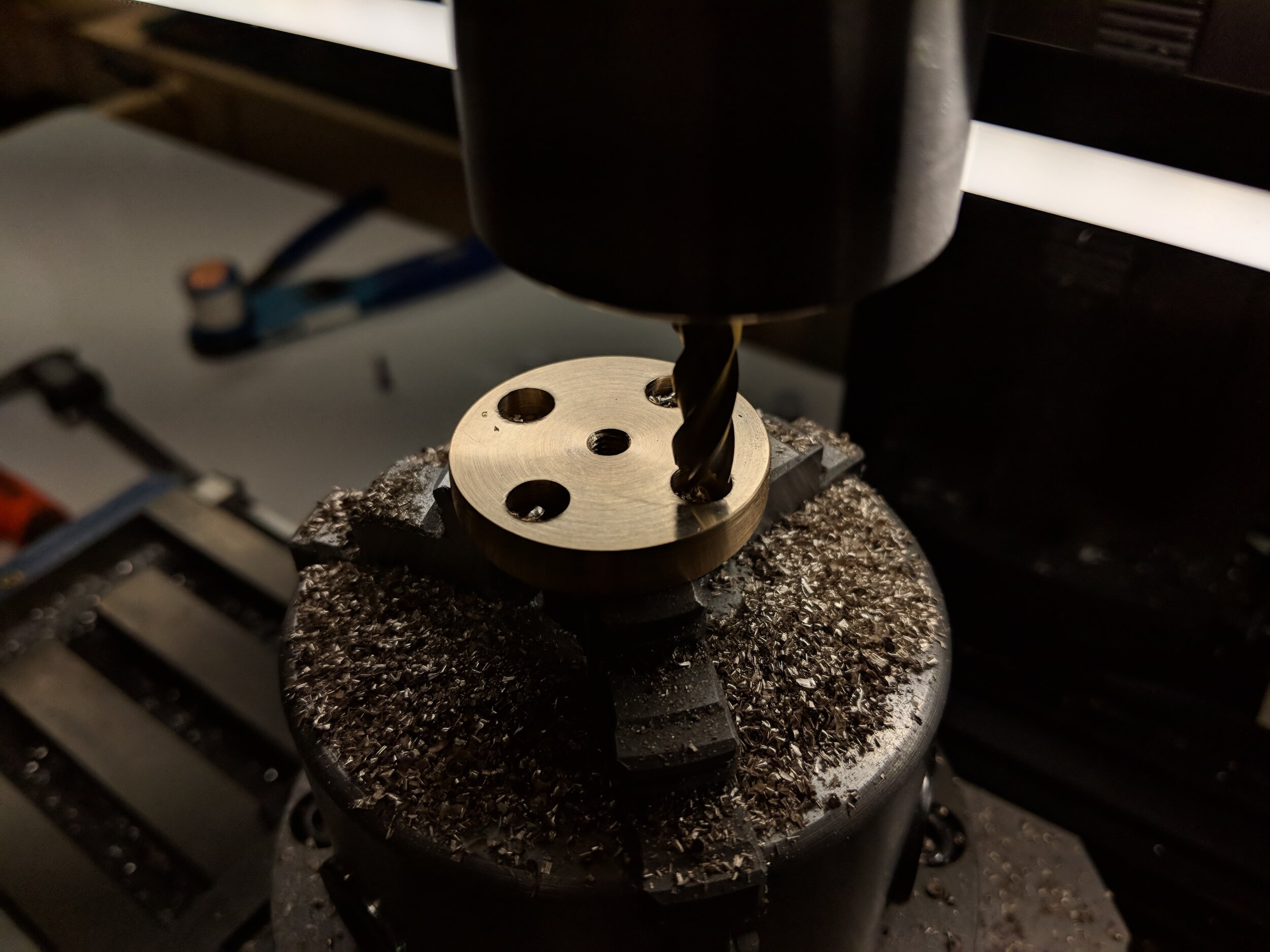

Circular Hole Patterns

Rotary Symmetrical Features

Repeat any other features at angular intervals (30°, 60°, 17.2°). Perfect for making hexagons, dials, and knobs.

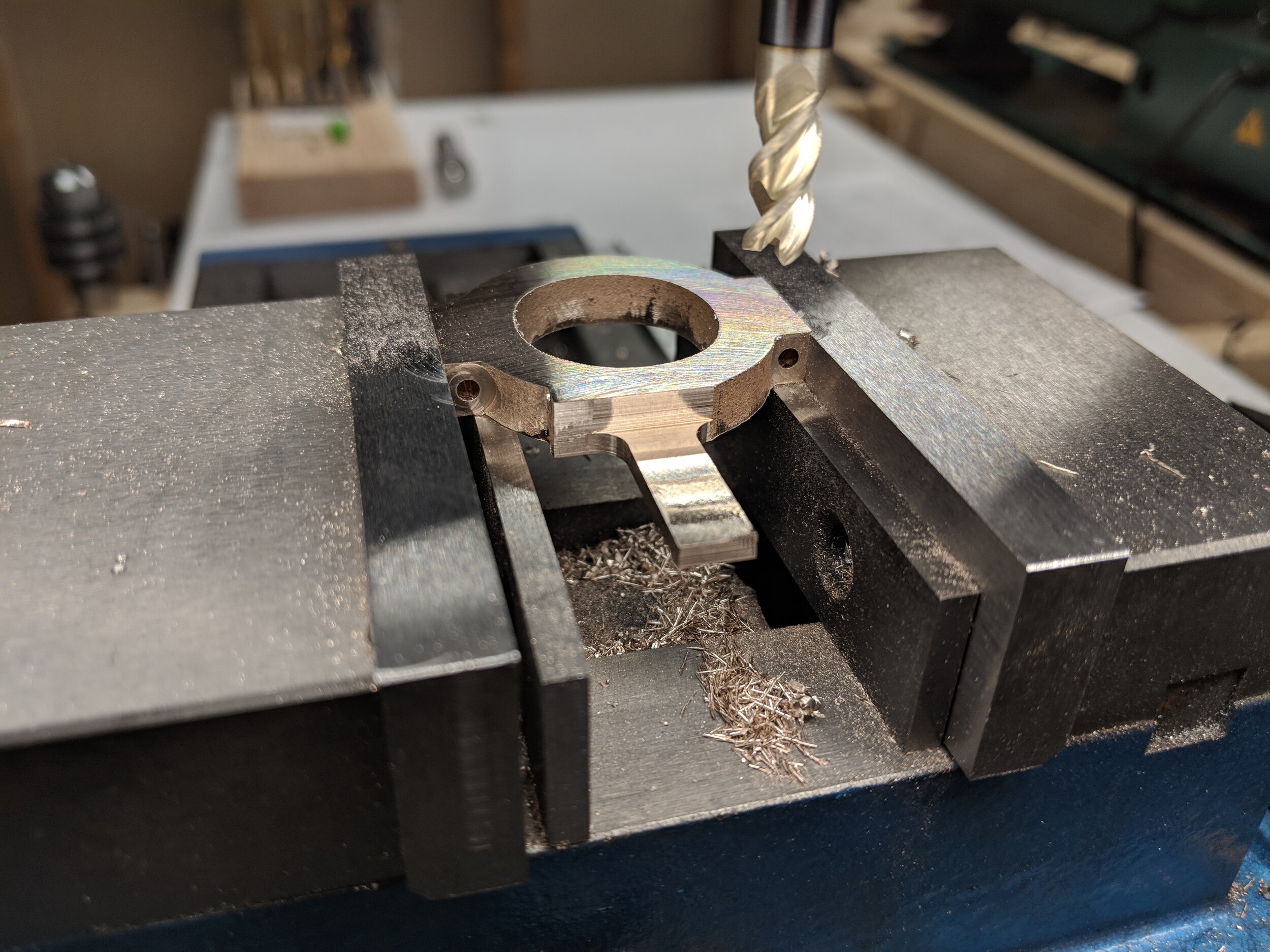

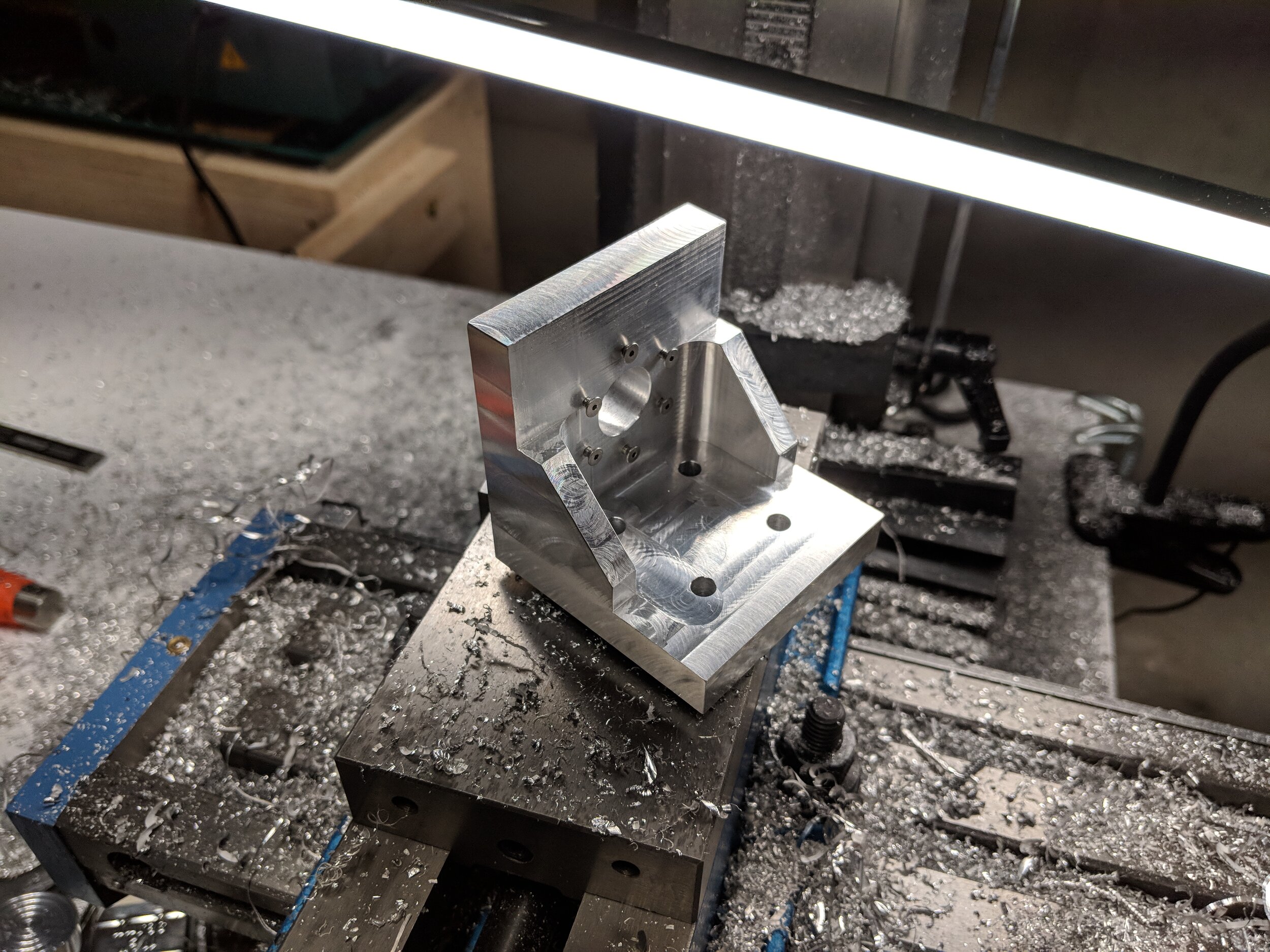

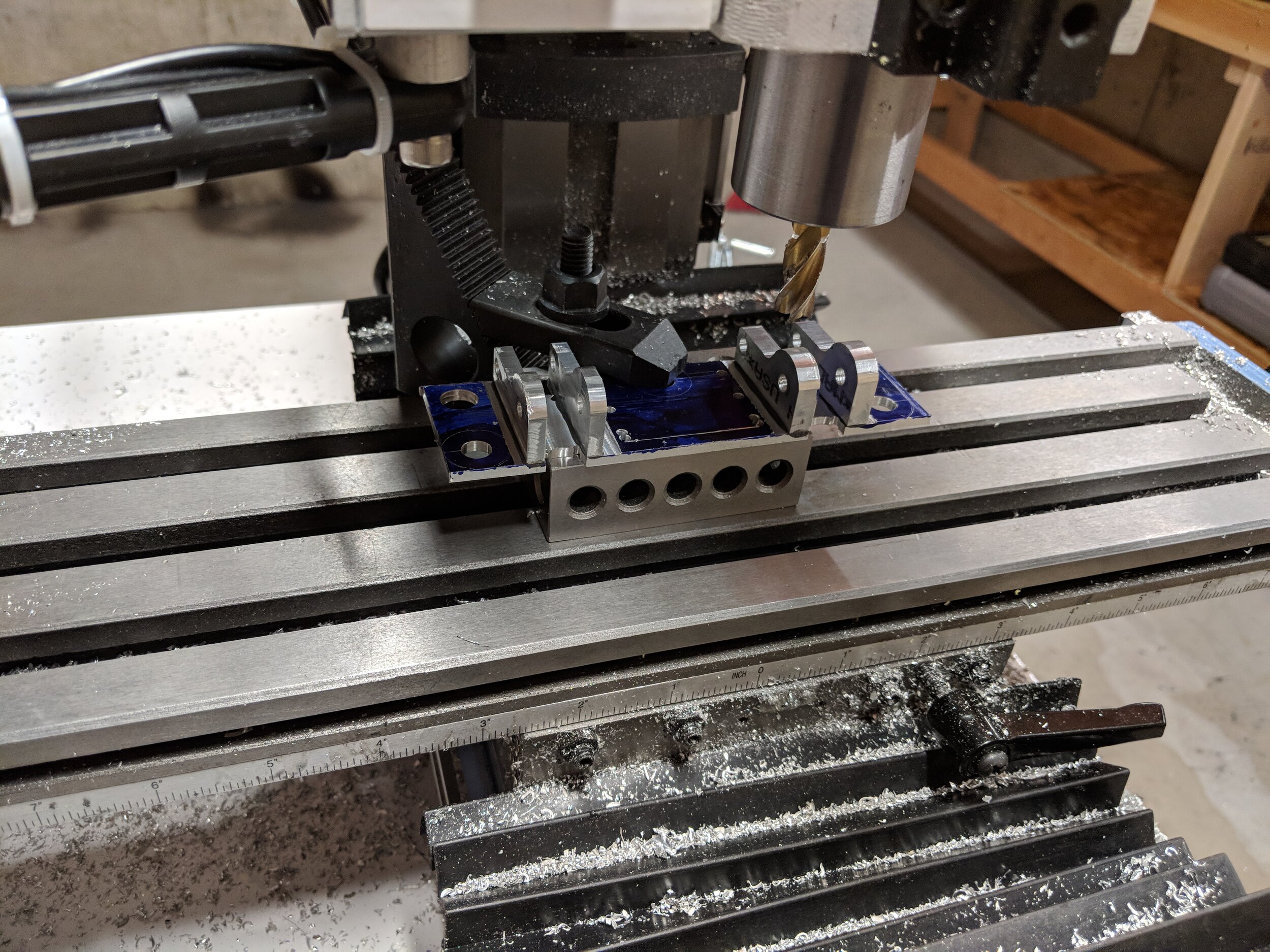

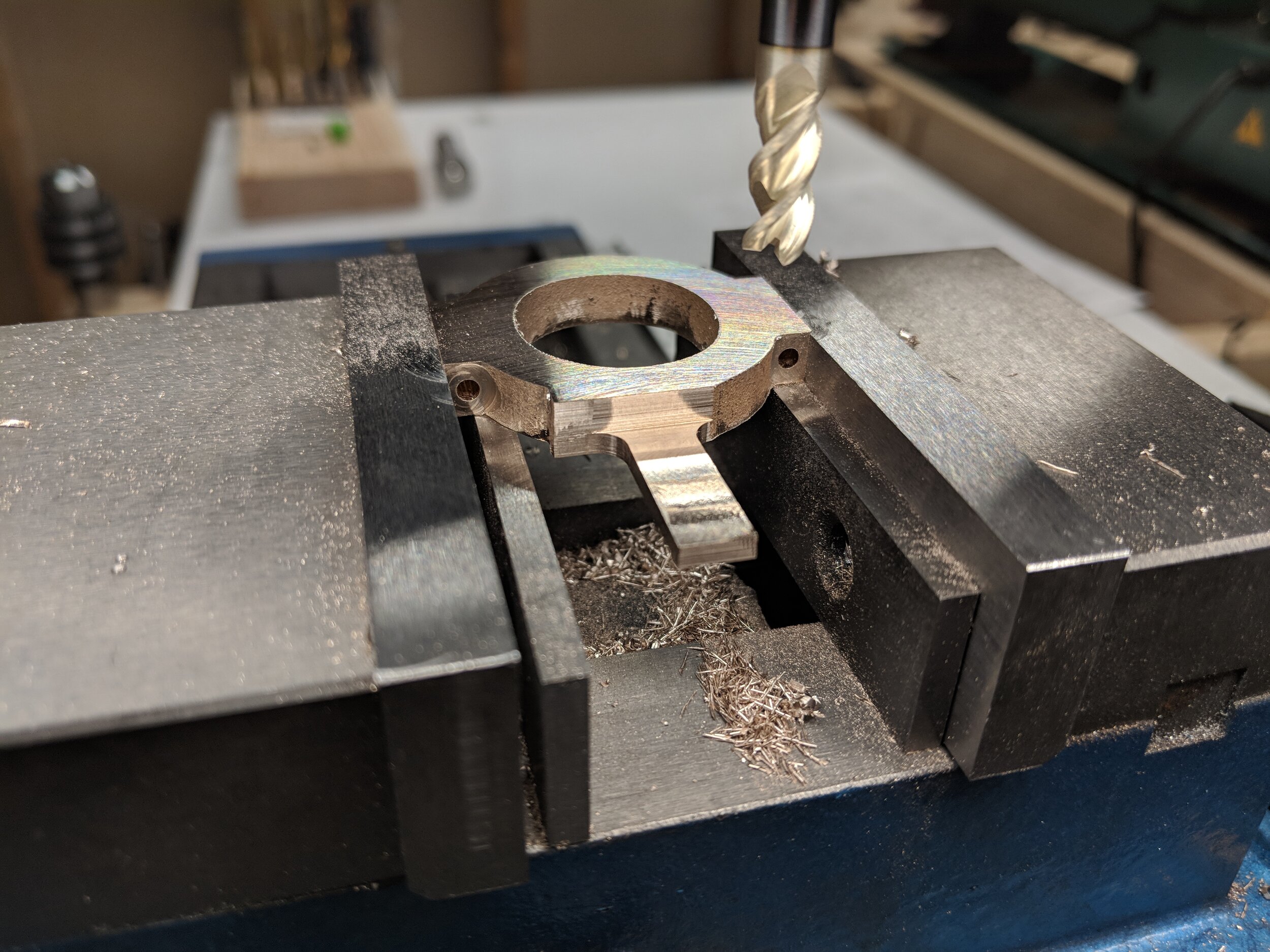

Milling Gallery