Lathe Turning

Lathes have a number of operations that can be performed to produce the part you want, but they all involve holding the part in a spinning chuck and moving cutting tools around it to remove material. We’ll figure out which ones to use, but here’s an idea of what’s possible with these machines.

Materials: Metals (Steel, Brass, Stainless, Titanium), Plastics

Uses: Rotationally symmetrical parts

Part Complexity: Simple shapes, highest accuracy

Cost: $60 per hour

Maximum Part Size: 9.5 (250mm) in diameter x 29.5 in (750mm) long

Looking for lower cost but fewer materials? Try FDM 3D Printing

Is your part more rectangular than cylindrical? Try Milling

Lathe Processes

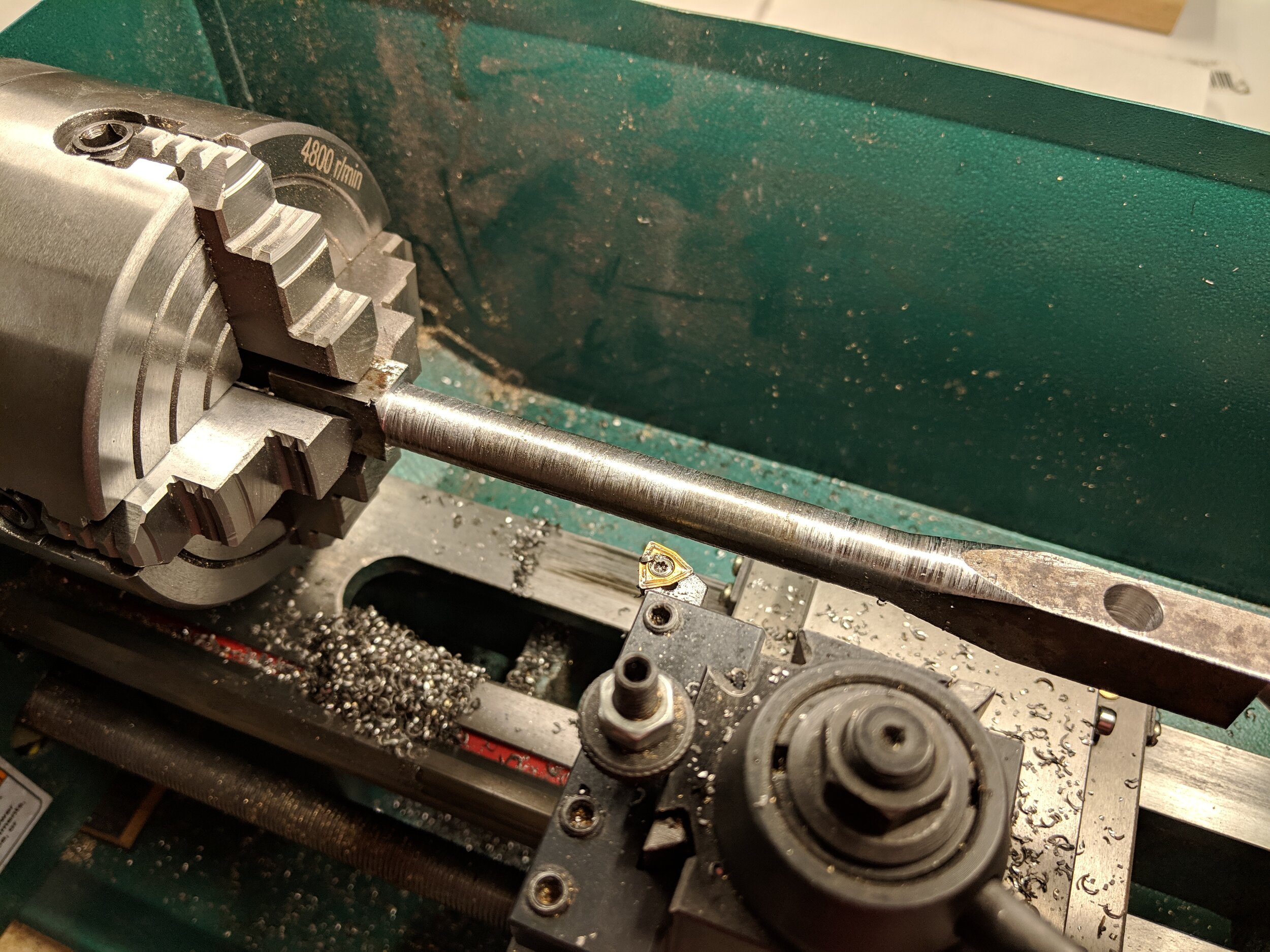

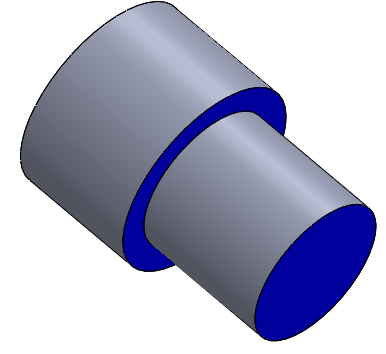

Outer Diameter Turning

OD Turning is very quick and extremely precise, one of the most straightforward operations a lathe can do.

Facing

Facing is the other very common lathe operation, for making flat ends and shoulders.

Blind Hole

Blind holes are holes that do not go all the way through the part. They generally have an angled bottom left from the drill point.

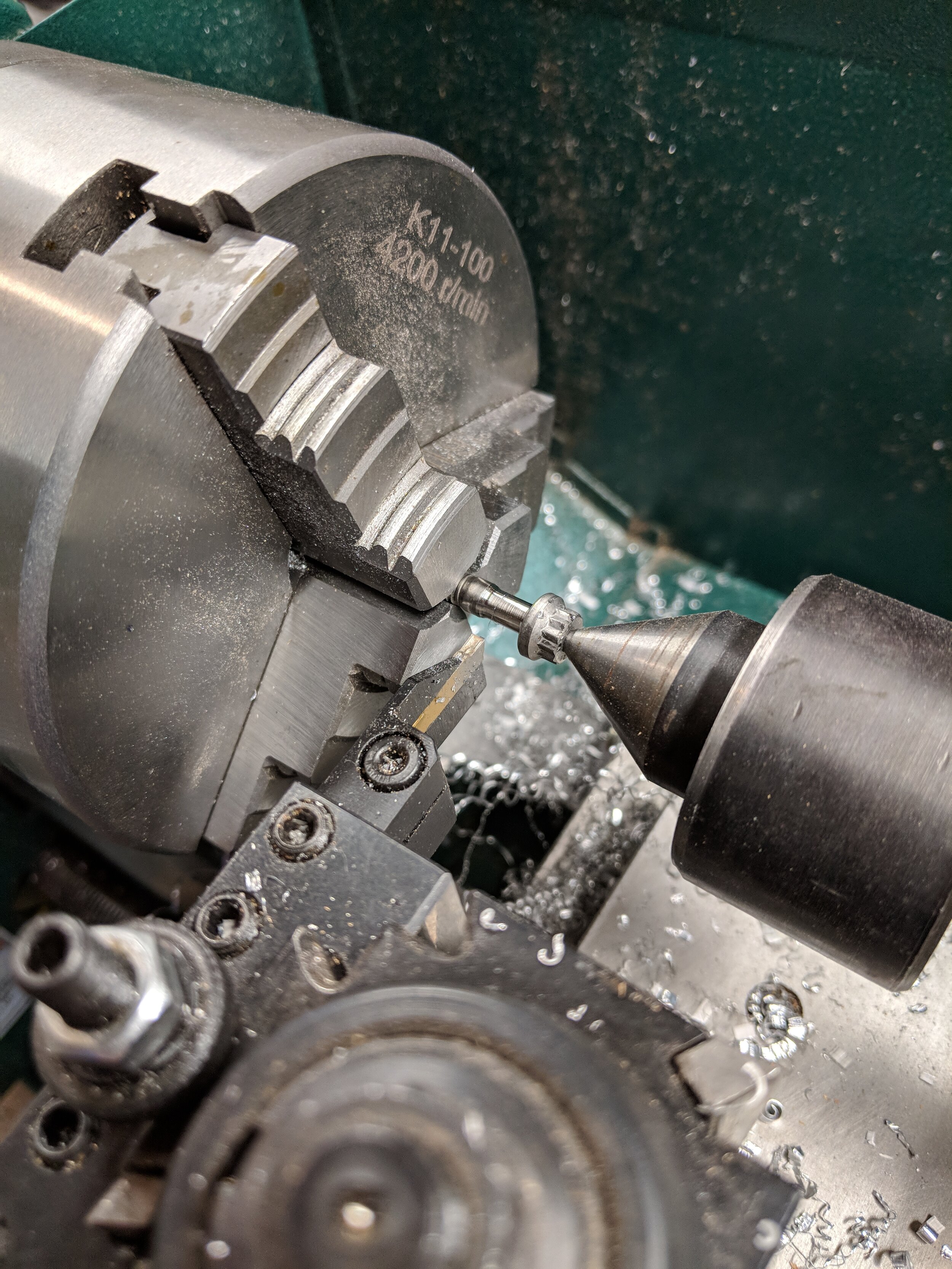

Thru Hole

Through holes go all the way through the part.

Blind Tap

Blind tapping leaves threads almost to the bottom of a hole. There is a small distance at the very bottom left unthreaded.

Partial Tap

Partial tapping produces threads in a through hole. It is less difficult than blind tapping as the chips can exit out the bottom of the hole.

External Thread

External threads can be made using either a die or single point cutter. A relief groove is generally needed to exit the thread.

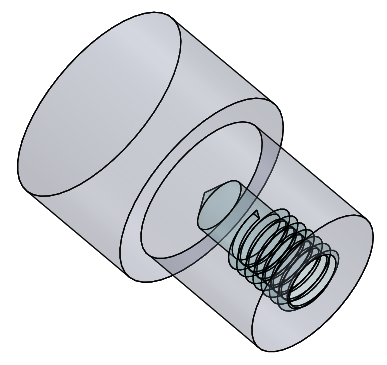

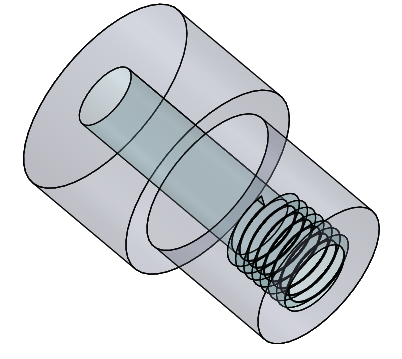

Boring

Boring enlarges an existing hole to a specific diameter. It is slower but more accurate than drilling a larger hole.

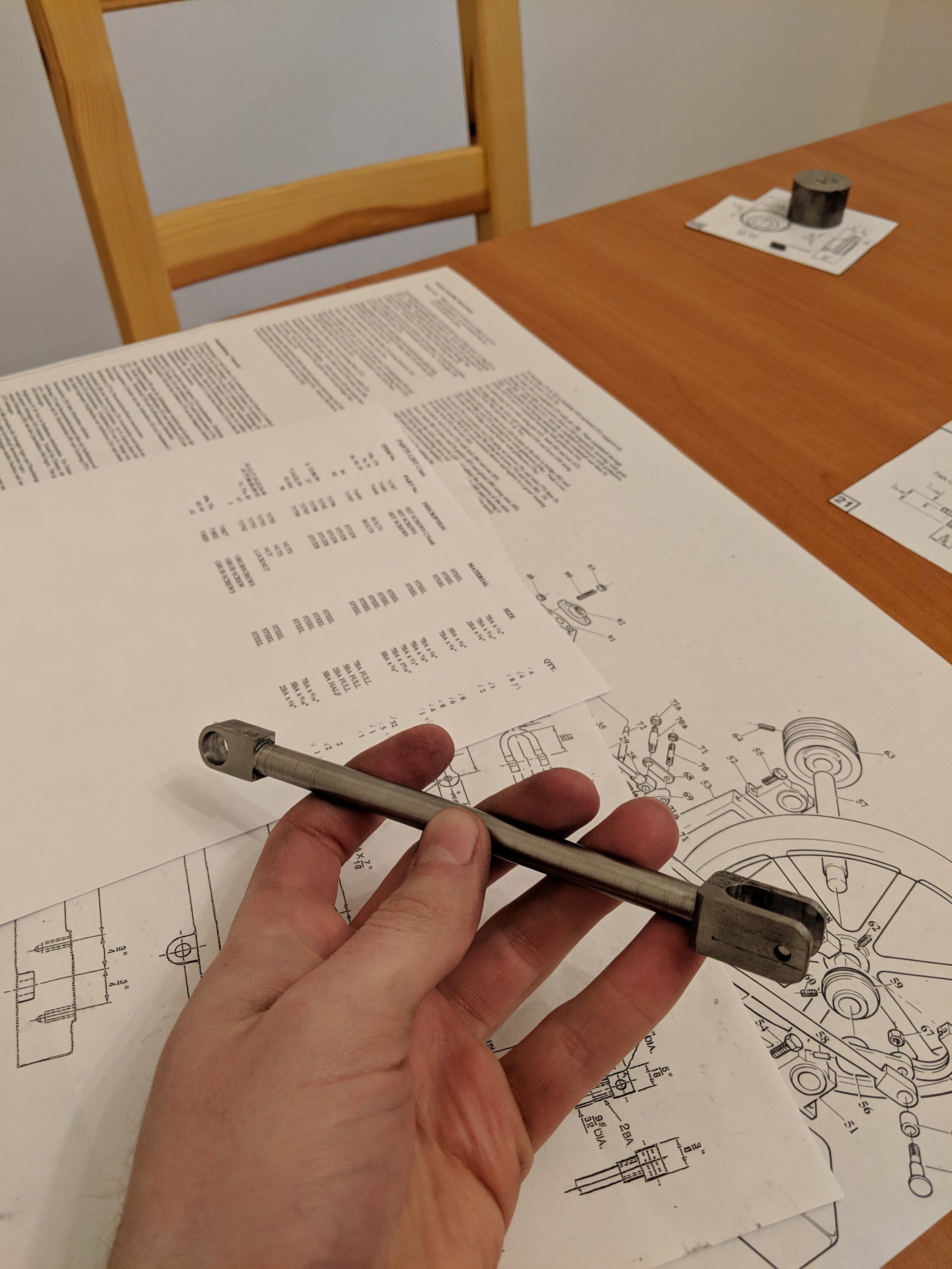

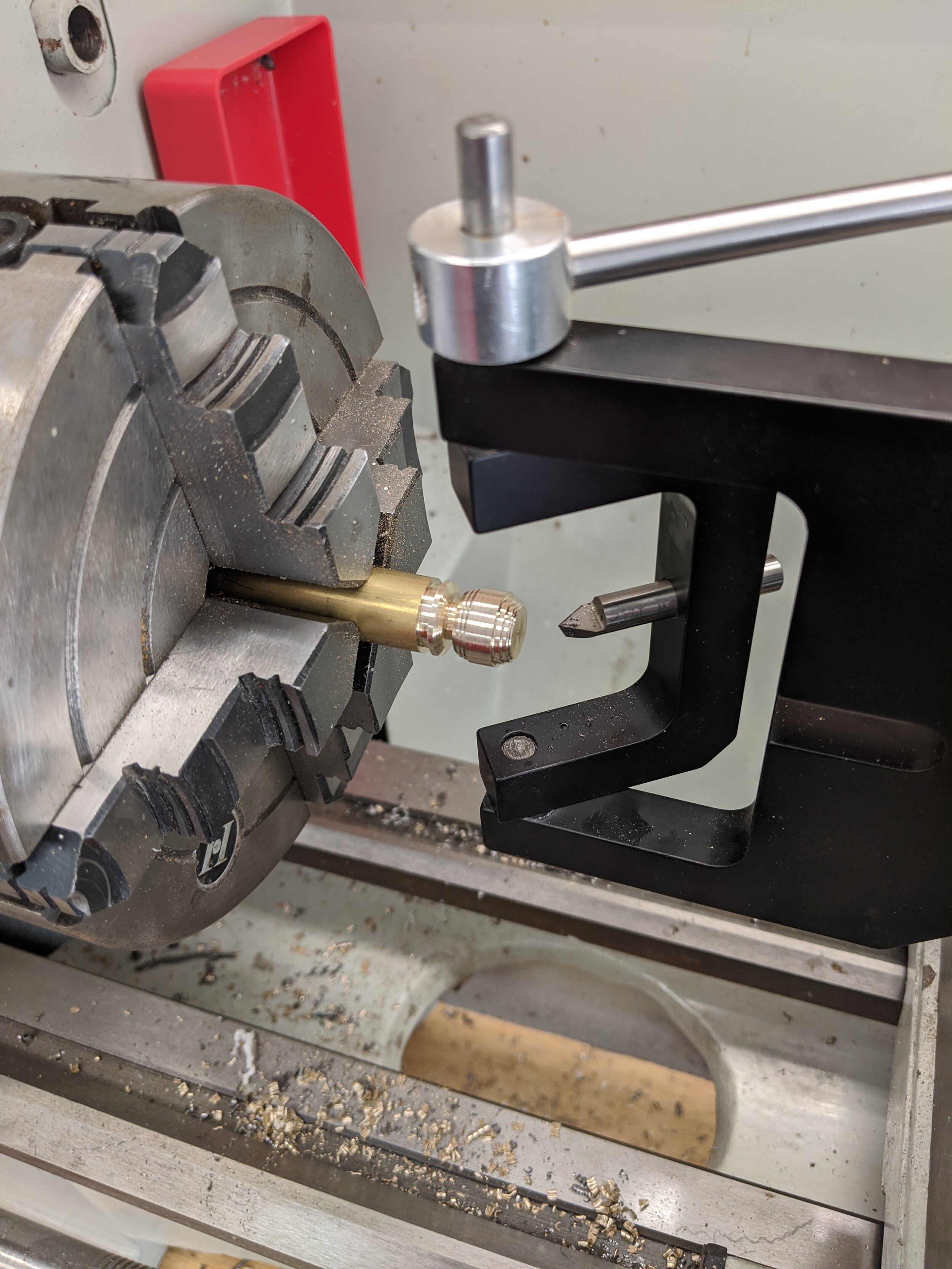

Lathe Gallery